Manufacturing, Engineering & Technology Cluster

Engineering & Automation Technology

About This Program

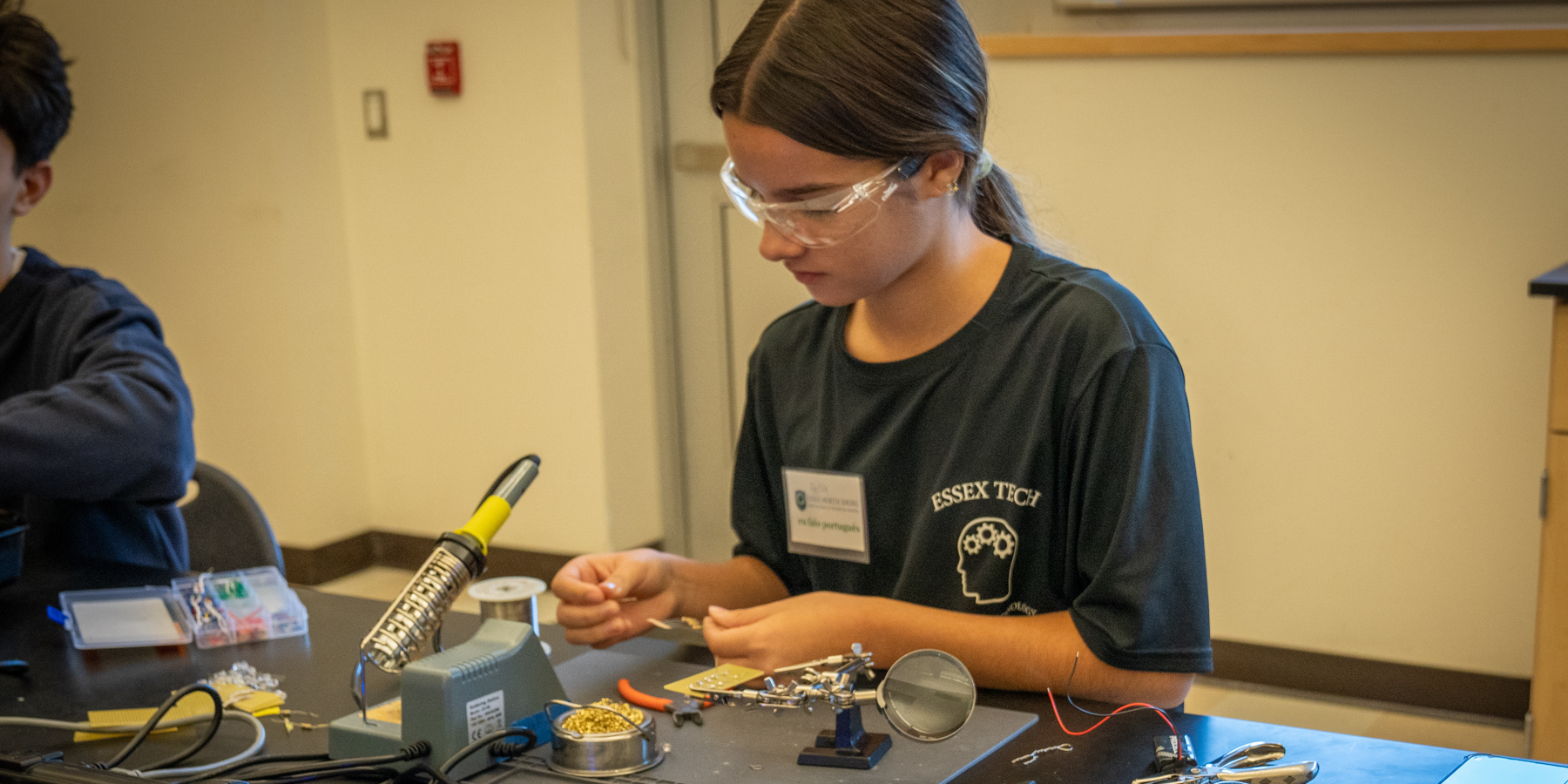

Engineering Technology & Automation Technology is a new Chapter 74 Career and Technical program (Fall 2018) for students who are interested in understanding the design processes and applying them with real-world experiences in robotics, CNC machining, and CAD. Students in this program will learn skills related to electrical, mechanical, and manufacturing engineering, including the components and process of a system, technical writing, blueprint reading and design, and project management. Students will develop a working knowledge of electrical engineering principles and the use of 3D modeling, laser and plasma cutting, precision metal, and basic welding methods. See below for full course descriptions.

Career Paths

- Mechanical Engineers

- Industrial Engineers

- Electrical and Electronic Engineers

- Electro-Mechanical Technicians

- Aerospace Engineers

- Computer Hardware Engineers

- Robotics and Automation

- CNC Machine Technicians

Industry Partnerships

- Item 1

Certifications

- Item 1

Articulation Agreements

- Bunker Hill Community College

- Northern Essex Community College

- North Shore Community College

Advisory Committee Members

- Jaiden Anja

- Austin Bisegna

- Robert Bisegna, The Gillette Company LLC

- Kaitlin Boland, WSE Engineers

- Russ Caswell, Weir Valve and Controls

- Gregg Cohen

- Susan Curry, North Shore

- Brian DeMatteo, L3 Advanced Programs

- James Galante ENSATS

- Kathryn Garnavish, Medtronic

- Kenny Ikuomenisan, North Shore Community College

- Bailey Kaplan, Synventive

- Jessica Kaufman, Endicott College

- Dave Kempskie, AET Labs

- Jacob Krajeski

- Mark Lyons, AET Labs

- Bradley Mingels, UMass Lowell College of Engineering

- George Moriarty, Center for Corporate and Community Education – Nor

- Michael Norcott

- Robert Pelletier, Heritage Environmental Services

- Sandro Russo, Prattville Machine

- Mary Sarris, North Shore Workforce Investment Board

- Wayne Spritz, AW Chesterton Company

- Ian Uva

- Nicholas Vlismas, PV Engineering & Mfg., Inc.

Meeting Documents

Meet the Engineering & Automation Teachers

Ms. Kerrie Abate

Robotics & Automation Technology Teacher

[email protected]

Mr. Merrill (Patrick) McColl

Engineering Teacher

[email protected]

Engineering & Automation Technology Course Descriptions

| Course Number | Name | Credit | Grade Level |

|---|---|---|---|

| eng101 | Engineering Exploratory 9 | 1 | Grade 9 |

| eng103 | Engineering Technology 9 | 10 | Grade 9 |

| eng200 | Engineering Technology 10 | 16 | Grade 10 |

| eng201 | Engineering Technology Theory 10 | 4 | Grade 10 |

| eng300 | Engineering Technology 11 | 20 | Grade 11 |

| eng301 | Engineering Technology Theory 11 | 4 | Grade 11 |

| en305 | Engineering Technology Cooperative Education 11 | 12 | Grade 11 |

| pmet301 | CTAE Pathway: Communication & Career Essentials | 2 | Grade 11 |

| pmet302 | CTAE Pathway: Business Finance Professional Financial Literacy | 2 | Grade 11 |

| eng400 | Engineering Technology 12 | 20 | Grade 12 |

| eng401 | Engineering Technology Theory 12 | 4 | Grade 12 |

| eng405 | Engineering Technology Cooperative Education 12 | 24 | Grade 12 |

| pmet401 | CTAE Pathway: Civic Humanitarianism | 2 | Grade 12 |

| pmet402 | CTAE Pathway: Professional Portfolio Presentation | 2 | Grade 12 |

Engineering Exploratory 9

Course # eng101 | Credits: 1

This five-day cycle exploratory course provides grade 9 students with an introduction to the Engineering Design Process and engineering projects. Major areas of focus are on how to transform an idea to a tangible design. Students demonstrate their learning through a series of engineering projects and identify the design process steps as they transition through each project to completion.

Engineering Technology 9

Course # eng103 | Credits: 10

This semester-based course emphasizes the role of engineering in modern-day society. The major focus of study is on helping students to understand what is behind the engineering design process and to reinforce this understanding through the various lessons and projects that students will complete. Students will begin by focusing on hand sketching an engineering concept and then applying that technique to brainstorming and developing both the criteria and constraints to a particular design. These steps are then repeated on mini-projects to strengthen student understanding of how to solve an open-ended problem. The skills developed in this course will foster the understanding necessary for continued growth in the engineering program.

Engineering Technology 10

Course # eng200 | Credits: 16

This full-year course provides students with an overview of engineering design and manufacturing. Major units of study include engineering drawings, computer-aided design (CAD), and computer-aided manufacturing. Students demonstrate their learning through developing three-dimensional CAD models and applying these to the manufacturing process. Students will learn to develop prototypes using 3-D printers, lasers, and computer numerically-controlled milling machines and lathes and other fabrication techniques.

Engineering Technology Theory 10

Course # eng 201 | Credits: 4

This full-year, classroom-based course embeds instruction in the theory behind the engineering projects students develop. The focus is on the theories behind computer-aided design (CAD) and in the equipment used to develop prototypes. Developing sketch constraints to match design intent, rules of dimensioning, and which strategy to incorporate when developing a three-dimensional model are demonstrated for CAD. Manufacturing theory involves the functionality of the different manufacturing processes, G-code, and the related math needed to form their prototypes. The connection between fit, form, and function from the development of a design to the execution of the prototype are emphasized.

Engineering Technology 11

Course # eng300 | Credits: 20

This full-year course instructs students in two major engineering disciplines; mechanical, and electrical engineering. The mechanical engineering focuses on the principles of engineering technology, and introduces topics on stress and strain, force distribution, factor of safety and failure analysis using finite element analysis. The electrical engineering focuses on circuit theory, combinational and sequential logic, and programming. Students identify the theory behind engineering principles and enforce that learning through interactive projects.

Engineering Theory 11

Course # eng301 | Credits: 4

This full-year, classroom-based course will explore electronic circuits that are used to process and control digital signals. The focus of the course is to expose students to the process of combinational and sequential logic design, teamwork, communication methods, engineering and technical standards and documentation. Students will apply digital concepts to control systems and through programmable logic boards and robotic automation.

Engineering Cooperative Education 11

Course # en305 | Credits: 12

This semester-based course provides qualified students with a career technical employment opportunity. The program is designed to allow students on-the-job training by involving them in work that is directly related to their technical area of study. Cooperating employers provide additional training, pays students, and reports their performance to the school for every cycle. Please note that juniors are eligible for Cooperative Education during third and fourth quarters only.

Engineering Technology 12

Course # eng400 | Credits: 20

The full-year course is designed to help students fine tune their Engineering Technology experience by having them pursue their own personal interest in the area of engineering. The primary focus will be product development and design. Students will follow the Engineering Design Process, working from idea generation through the prototyping and testing processes. Seniors will have full access to engineering and manufacturing equipment to assist in the development of their design projects.

Engineering Theory 12

Course # eng401 | Credits: 4

This full-year, classroom-based course will explore engineering design by creating computer-aided drawings (CAD) using AutoCAD and SolidWorks, and acquiring programming language skills. Students will also study the theory behind basic machine principles and programming related to the operation of the CNC mill and lathe.

Engineering Cooperative Education 12

Course # eng405 | Credits: 24

This full-year course provides qualified students with a career technical employment opportunity. The program is designed to allow students on-the-job training by involving them in work that is directly related to their technical area of study. Cooperating employers provide additional training, pays students, and reports their performance to the school for every cycle.